Tag: JLN Safety

-

Confined Space Rescue Training Built on Real-World Experience

•

At JLN Associates, LLC, we are proud of our confined space rescue teams who work across the country every day—supporting industrial facilities, power generation sites, construction projects, and municipal operations. […]

-

Winter Industrial Safety Planning for Power Generation & Manufacturing Facilities

•

Why Winter Requires a Different Safety Strategy Winter introduces a unique set of operational and safety challenges for power generation and manufacturing facilities. Cold temperatures, snow, ice, reduced daylight, and […]

-

“We’ve Always Done It This Way”: The Most Dangerous Phrase in Safety

•

In the world of safety, few phrases raise more red flags than:“We’ve always done it this way.” It’s often said with good intentions – by experienced workers who take pride […]

-

Case Study: The Callide Power Station Explosion – When Safety Takes a Back Seat

•

On April 4, 2021, a catastrophic explosion at Australia’s Callide Power Station ripped through the facility, leaving behind an expensive trail of damage, lost generation capacity, and most importantly—serious questions […]

-

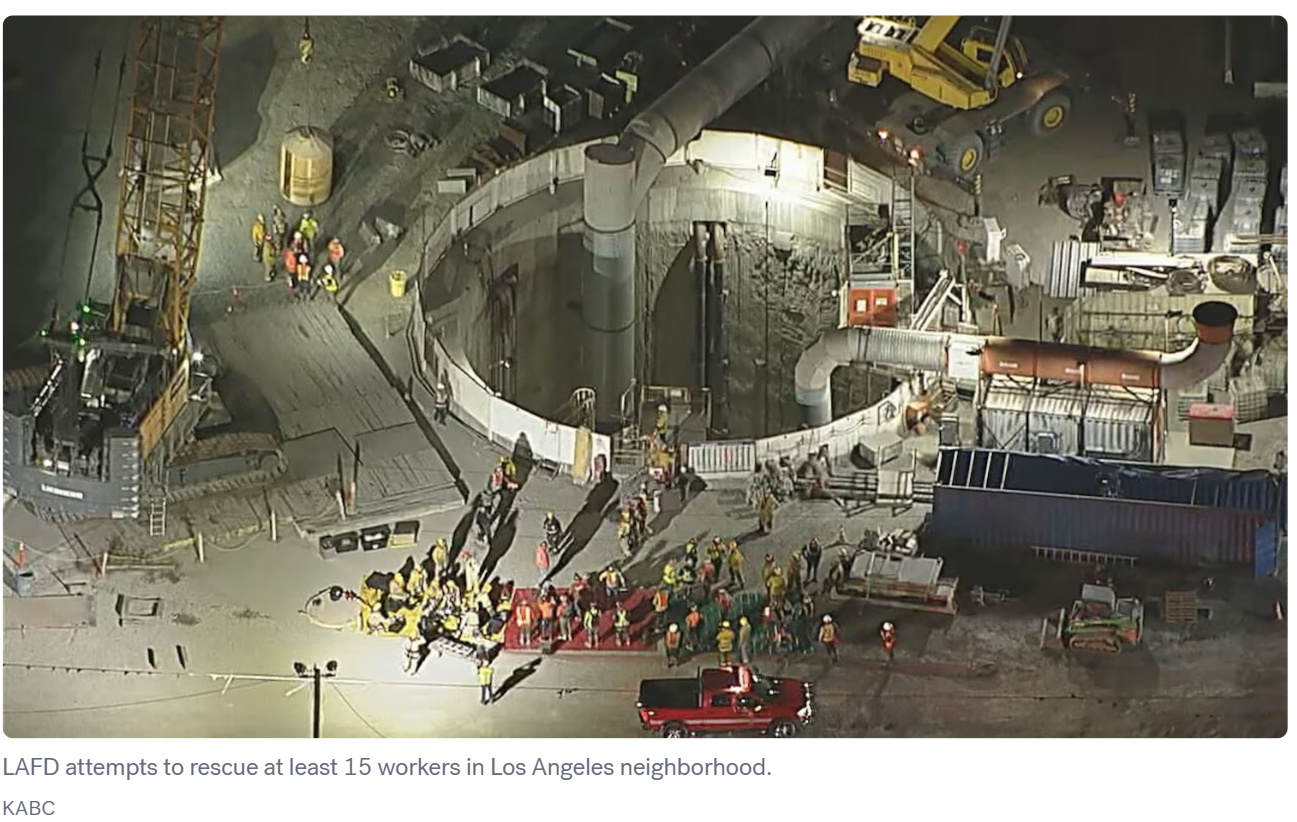

When Seconds Count: What the LA Tunnel Rescue Taught Us About Industrial Emergency Readiness

•

Last week, headlines broke about a terrifying tunnel collapse in Los Angeles, where a group of underground construction workers became trapped deep inside a tunnel – six miles from the […]

-

What You Need to Know About Confined Space Rescue (Before It’s Too Late)

•

Confined spaces don’t give second chances. Whether it’s a tank, tunnel, silo, or vault, these environments can turn deadly in seconds – making confined space rescue one of the most […]

-

Training That Saves Lives: What Sets JLN Safety’s Programs Apart

•

In industrial environments where a single misstep can mean serious injury – or worse – safety training isn’t just a formality. It’s a lifeline. When seconds count, training matters. Yet […]

-

Why Every Outage Needs a Third-Party Safety Partner

•

The High-Risk Environment of Plant OutagesIndustrial plant outages – whether planned or emergency – are some of the most critical and high-risk windows in a facility’s operational calendar. Crews work […]

-

Real Results: Before & After Site Safety Interventions by JLN Safety

•

When it comes to safety, seeing really is believing. At JLN Safety, we’re not just consultants – we’re on-the-ground problem-solvers. Our role as a third-party safety partner means we walk […]

-

OSHA Requirements for Confined Space Rescue: What Your Company Needs to Know

•

Confined space rescues can turn deadly—fast. Learn why OSHA requires trained standby teams and how JLN Safety exceeds those standards to save lives